Mechanical resistance tests

We offer:

Products´ resistance tests for linear acceleration, vibration, shocks, including combine load with climatic effects:

- Vibration tests

- Resonance determination

- Shocks

- Accident safety

- Combined tests (vibration, shocks, temperature, humidity)

- Linear acceleration

Equipment (selection):

- Electrodynamic vibration and shock device LDS V890-LPT900 COMBO (max. static load up to 700 kg, frequency range 1 – 2,300 Hz, peak force at sinusoidal vibration 53.4 kN, RMS force at random vibration 55.6 kN, peak force at half-sinusoidal shock 166.8 kN, max. deviation amplitude 25.4 mm, speed 1.6 m.s-1, acceleration 392 m.s-2, scattered magnetic field < 2.0mT)

- Electrodynamic vibration and shock device TIRA S597/LS-340 (max. static load 610 kg, frequency range DC – 3,000 Hz, peak force at vibration 35 kN, at shock 70 kN, max. deviation amplitude 25.4 mm, max. velocity amplitude at vibration 1.8 m.s-1, at shock 2.5 m.s-1, max. acceleration amplitude 110 g, at shock 220g)

- Electrodynamic vibration and shock device LDS V850-440 HBT600 COMBO (max. weight of the specimen under test 350 kg, usable frequency range 1 – 3000 Hz, peak sine force 22,2 kN, max. RMS random force 22,2 kN, peak shock force 66,7 kN, max.velocity 2 m.s-1, max. acceleration 600 m.s-2)

- Climatic chamber CTS (-70 to 180 deg C, relative humidity 10 to 95 %, temperature variation rate 2 K.min-1, dimensions (width x height x depth) 1200 x 1050 x 1100 mm, two openings for cables 12 cm dia, max. bottom load 150 kg.m-2

- Temperature chamber Vötsch VTV 7060-5 (temperature -70 to 180°C, temperature change rate 5 K.min-1, -dimensions (w/l/h) 800×950×800 mm, -holes for cabling, diameter 12cm)

- Vibration control systems SD 2552B (8 inputs for vibration control and test monitoring) and VR8500 and VR8500-8 (4 and 8 inputs for test control and monitoring)

- SMK1 centrifuge (mass of article tested max. 50 kg, its max. dimensions 500 x 500 x 500 mm, acceleration range 0.5 – 25g)

Standards (most frequent types of tests):

| ČSN EN 50125-1 | Railway applications - Environmental conditions for equipment - Part 1: Equipment on board rolling stock |

ČSN EN 50155 |

Railway applications - Electronic equipment used on rolling stock |

ČSN EN 60068-2-6 |

Environmental testing - Part 2: Tests Fc: Vibration (sinusoidal) |

| ČSN IEC 68-2-7 | Elektrotechnical and elektronic products. |

| ČSN EN 60068-2-27 | Basic environmental testing procedures. Part 2: Tests. Test Ea and quidance: Shock |

| ČSN EN 60068-2-29 | Basic environmental testing procedures. Part 2: Tests. Test Eb and guidance: Bump |

| ČSN EN 60068-2-47 | Environmental testing - Part 2-47: Tests - Mounting of specimens for vibration, impact and similar dynamic tests |

| ČSN IEC 68-2-50 | Basic environmental testing procedures - Part 2: Tests - Tests Z/AFc: Combined cold/vibration (sinusoidal) tests for both heat-diddipating and non-heat-dissipating specimens |

| ČSN IEC 68-2-51 | Basic environmental testing procedures - Part 2: Tests - Tests Z/BFc: Combined dry heat/vibration (sinusoidal) tests for both heat-dissipating and non-heat-dissipating specimens |

| ČSN IEC 68-2-53 | Basic environmental testing procedures - Part 2: Tests - Guidance to Tests Z/AFc and Z/BFc: Combined temperature (cold and dry heat) and vibration (sinusoidal) tests |

| ČSN EN 60068-2-57 | Environmental testing - Part 2-57: Tests - Test Ff: Vibration - Time-history method |

| ČSN EN 60068-2-59 | Environmental testing. Part 2: Test methods - Test Fe: Vibration - Sine-beat method |

| ČSN EN 60068-2-64 | Environmental testing. Part 2: Test methods. Test Fh: Vibration, broad-band random (digital control) and guidance |

| ČSN EN 61373 | Railway applications - Rolling stock equipment - Shock and vibration tests |

| RTCA/DO-160 | Environmental Conditions and Test.Procedures for Airborne Equipment |

| MIL-STD-810 | Environmental Engineering Considerations and Laboratoty Tests |

| VW 80101 | Electrical and Electronic Assemblies in Motor Vehicles. General Test Conditions |

Customers:

- Tests for aviation and non-aviation sectors, particularly for the car industry

- Rolling stock

- Electronics and electrical engineering manufacturers

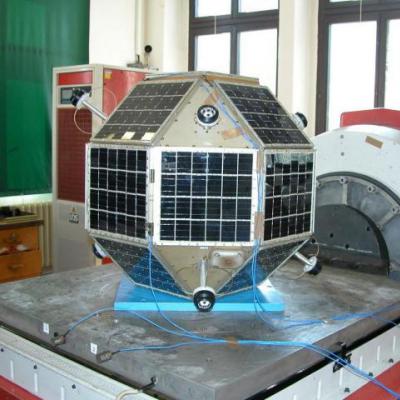

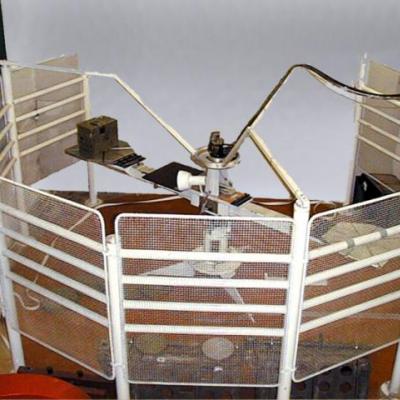

- Space industry

- Aviation engineering operators

- Test on hydraulics elements and circuits

- LPG and CNG fuel systems tests

Contact:

Ing. Miroslav Valeš, Ph.D.

director of VZLU TEST, a.s.

Tel: +420 225 115 267, fax: +420 225 115 430

e-mail: vales@vzlutest.cz

Ing. Richard Vilikus

Head of Mechanical Ruggedness Testing Laboratory

Tel: +420 225 115 190, +420 736 503 259, fax: +420 225 115 430

e-mail: vilikus@vzlutest.cz

Activities

of our company

Files

to download